Shop

Cheese ripening guide

- How to bring a soft curd with a bloomy mold rind to its optimum taste?

- How to get a creamy layer under the rind?

- When is it more appropriate to use static or ventilated refrigeration?

- How to inoculate a ripening cellar?

- How to make a smear?

One of a kind, sometimes reference technical work and sometimes field work, this guide provides concrete and pragmatic answers for all the big cheese families.

Written in simple language and accessible, it thus alternates general scientific knowledge, practical tips, implementation diagrams, testimonials from professionals, diagnostics and defect resolution sheets.

To those who want to embark on ripening, it will give the keys to understanding and reaction.

To those who already practice this art where the sense of the observation is preponderant, it will bring new insights and will allow them to perfect their practice.

Authors:

Arnaud Sperat-Czar is the publisher and editor-in-chief of the magazine « Profession Fromager ».

Sébastien Roustel, technologist and trainer, is in charge of development of cheese technology at CHR-Hansen.

He was previously the head of the Research and Development Department of Enilbio in Poligny.

Débora Pereira is a journalist, a researcher in information sciences and collaborator of « Profession Fromager».

She runs the association «Sertaobras», which works to promote the Brazilian cheese heritage.

The book benefited from the advice and careful reading of Bernard Mietton, renowned French technologist.

Les pâtes pressées pas à pas

This practical guide offers, in very concrete terms, recipes for a dozen iconic cheeses from this large family:

Tomme grise, Trappist, Raclette, Cheddar, Gruyère style…Cheesemaking technologist and instructor by profession, equally expert in the artisanal and industrial arenas, the author describes the precise steps to follow for each style, with adaptations and options throughout the process, including how to resolve occasional problems, while also including different configurations possible for equipment and tools.

Author:

Sébastien Roustel is a cheese technology expert at CHR-Hansen.

Prior to this he directed the research and development service at the Enilbio at Poligny.

He also wrote the guide “Soft Paste Cheese, Step-by-Step”, published in this same collection.

Soft cheese step-by-step

They often learn ‘on the job’.

This guide offers, in a precise, detailed, and accessible manner, step-by-step instructions for the main types of cheese that fall within this category.

Cheese technologist and educator with expertise in both the artisanal and industrial sectors, the author offers his understanding of the principles and his practical knowledge to the reader, taking care to offer detailed information about equipment, tools, and other requirements for successful cheesemaking.

He also lays out, step-by-step, optional adaptations to the cheesemaking process.

Author:

Sébastien Roustel is a cheesemaking technologist.

Le guide de l'affinage

- How to bring a soft curd with a bloomy mold rind to its optimum taste?

- How to get a creamy layer under the rind?

- When is it more appropriate to use static or ventilated refrigeration?

- How to inoculate a ripening cellar?

- How to make a smear?

One of a kind, sometimes reference technical work and sometimes field work, this guide provides concrete and pragmatic answers for all the big cheese families.

Written in simple language and accessible, it thus alternates general scientific knowledge, practical tips, implementation diagrams, testimonials from professionals, diagnostics and defect resolution sheets.

To those who want to embark on ripening, it will give the keys to understanding and reaction.

To those who already practice this art where the sense of the observation is preponderant, it will bring new insights and will allow them to perfect their practice.

Authors:

Arnaud Sperat-Czar is the publisher and editor-in-chief of the magazine « Profession Fromager ».

Sébastien Roustel, technologist and trainer, is in charge of development of cheese technology at CHR-Hansen.

He was previously the head of the Research and Development Department of Enilbio in Poligny.

Débora Pereira is a journalist, a researcher in information sciences and collaborator of « Profession Fromager».

She runs the association «Sertaobras», which works to promote the Brazilian cheese heritage.

The book benefited from the advice and careful reading of Bernard Mietton, renowned French technologist.

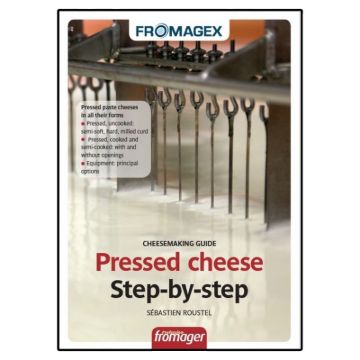

Pressed cheese step-by-step

This practical guide offers, in very concrete terms, recipes for a dozen iconic cheeses from this large family:

Tomme grise, Trappist, Raclette, Cheddar, Gruyère style…Cheesemaking technologist and instructor by profession, equally expert in the artisanal and industrial arenas, the author describes the precise steps to follow for each style, with adaptations and options throughout the process, including how to resolve occasional problems, while also including different configurations possible for equipment and tools.

Author:

Sébastien Roustel is a cheese technology expert at CHR-Hansen.

Prior to this he directed the research and development service at the Enilbio at Poligny.

He also wrote the guide “Soft Paste Cheese, Step-by-Step”, published in this same collection.

Stainless Steel Aging Racks 630 x 510mm, 31 wires, H100/120mm (Plastic legs)

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

Manual curd mill

Make cheese curds

The traditional cheese mill is a key part of the cheddar cheese curd process. It allows faster production for the cheesemaker.